Microencapsulation is widely used to manufacture prolonged-release dosage forms, pulsatile release dosage forms, and targeted drug delivery systems. Apart from this, it has some other standard Applications of microencapsulation that are listed as follows :

Applications of microencapsulation

- Encapsulation of the drug prevents its contact with the biological fluid unnecessarily and thereby improves the drug concentration in the blood. The drug’s effect is prolonged while the toxic effects are reduced due to reduced dosing frequency. These attributes are beneficial and aid in the sustained release of the drug.

- Microencapsulation can also use it to formulate pH-dependent dosage forms so that the drug will selectively act on the different regions of the gastrointestinal tracts. Enteric-coated microcapsules are preferentially absorbed in the intestine than in the stomach.

- It is also used to add oily medicines to tableted dosage forms as the conventional tablet compression methods would result in a tacky granulation.

The stability of eutectic mixtures that turn into a liquid formulation as they come in contact with each other can be maintained by microencapsulating the two drug constituents before mixing them. E.g., Aspirin and chlorpheniramine maleate are solids that turn into liquids when they come in direct contact with one another. To avoid this, both the drugs are microencapsulated before formulation.

- Microencapsulation of fumigants, germicides, pesticides, and insecticides reduces their toxicities and makes their handling much more convenient.

- Microencapsulating volatile ingredients prolong their shelf–life without substantial evaporation. E.g., Microencapsulated clove oil.

Difficulties in microencapsulation :

Although microencapsulation is a novel technique with many benefits, one cannot turn a blind eye to this technique’s disadvantages. Microencapsulating drugs have their array of problems that one must consider before proceeding into the manufacturing process.

The typical difficulties or setbacks one faces during microencapsulation are as follows :

- No single microencapsulation technique applies to all core material candidates, and hence you must do it with caution.

- Incomplete or discontinuous films are possible.

- Possibilities of reaction between the core and the coating material.

- Inadequate stability of shelf–life of the sensitive pharmaceuticals.

- Expensive to manufacture and unstable release characteristics of the coated product.

Read more:

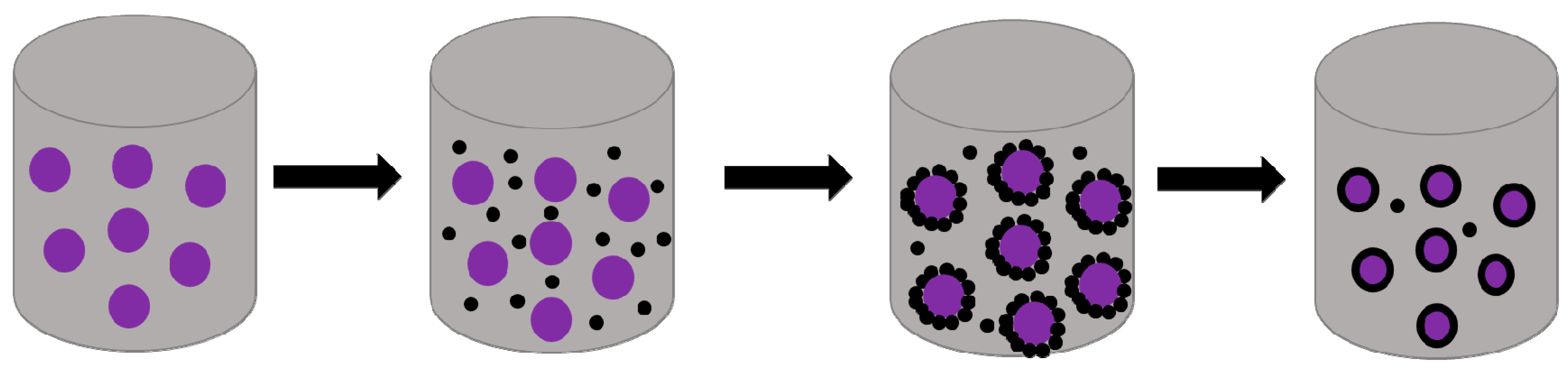

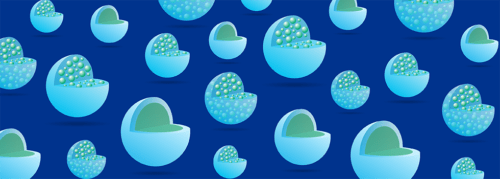

- Microencapsulation means applying relatively thin coatings to small particles of solids or droplets of liquids or dispersions. Read Microencapsulation: Advantages and disadvantages

- The method of microencapsulation depends on the core material, the application of the microcapsule, size of particles needed, release characteristics of the microcapsule, and the cost of production. Read Methods of Microencapsulation and Process

- Multiparticulate drug delivery systems consist of three common constituents: microparticles, microcapsules, and microspheres. These microcarriers do not traverse through the interstitium and therefore produce local action. Read Constituents of multiparticulate drug delivery system

- Article review

Pingback: Microencapsulation: Advantages and disadvantages > PharmaCampus

Pingback: Constituents of multiparticulate drug delivery system > PharmaCampus

Pingback: Methods of Microencapsulation and Process > PharmaCampus