The method of microencapsulation depends on the core material, the application of the microcapsule, size of particles needed, release characteristics of the microcapsule, and the cost of production. The commonly adopted microencapsulation techniques are :

Methods of microencapsulation

- Air suspension technique

- Coacervation – Phase separation

- Spray drying

- Spray cooling

- Multi – orifice centrifugal process

- Pan coating

- Solvent evaporation

- Polymerization

Let us discuss these Methods of microencapsulation in detail.

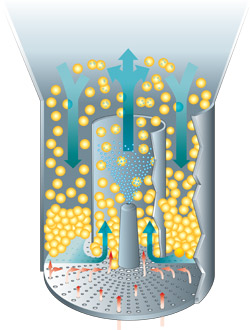

The Air Suspension Technique

The air suspension technique is also called the “Wurster process.” It consists of dispersing the solid, particulate core material in a supporting air stream with a simultaneous spray coating of the suspended particles. The particles are suspended using an upward stream of moving air in the coating chamber and recirculated in this chamber to receive an increment of the coating material during each cycle. The supporting air stream also aids in the rapid drying of the drug. Only solid materials can be used as the core material in this technique, and the final product size achieved ranges from 35 to 5000 microns.

Coacervation – Phase separation

Coacervation – Phase separation – This technique involves forming three separate phases, deposition of the coating polymer around the core, and finally rigidization of the coating by thermal or cross–linking techniques.

When a simple macromolecule is present in the core, it is called simple coacervation, but it is called complex coacervation when several macromolecules are present. It is a low-cost process that is used for encapsulating flavor oils. But this process can occur only within a limited pH range, colloidal concentration, or electrolyte concentration. This technique can encapsulate both solids and liquids to give microcapsules of 2 to 5000 microns.

Spray drying (As Methods of microencapsulation)

Spray drying – An emulsion, solution, or suspension of the core and coating material is first formed. The preparation is then nebulized in a drying chamber with circulating hot air for evaporation of the coating material and encapsulation of the core. Large-scale production of the microcapsules can be done at a low cost using this method. However, it can only produce microcapsules of 600 microns size, and these may not often be uniform in size.

Spray cooling

Spray cooling – A mixture of core and coating material is produced and nebulized by an atomizer. Following atomization, the droplets enter a chamber in which air is flowing at a lower temperature to facilitate solidifying the coating material to encapsulate the core. It is one of the cheapest microencapsulation techniques but has low encapsulation capacity with increased chances of the expulsion of the core during storage.

Multi–orifice centrifugal process

The Southwest Research Institute developed Multi–orifice centrifugal process. It uses centrifugal force to hurl the core material particle through the enveloping microencapsulation membrane. This process is used to encapsulate liquids and solids if the solids are dispersed in a liquid. This process can produce over 50 to 75 pounds of encapsulated products in an hour.

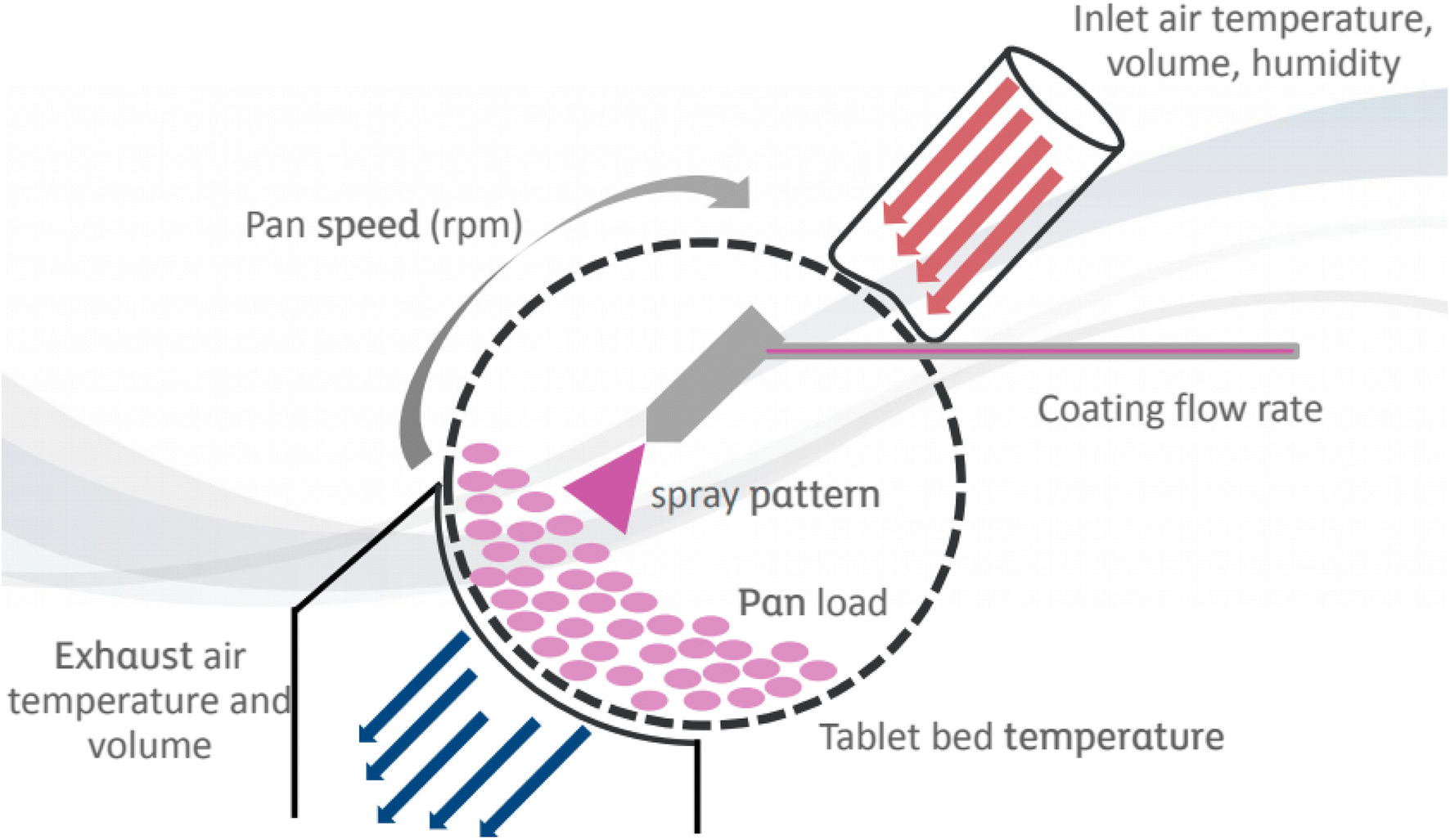

Pan coating (As Methods of microencapsulation)

Pan coating – Solid particles greater than 600 microns in size is effectively coated in a pan using this method. The coating material is generally applied as a solution or atomized and sprayed over the solid core material in the circulating pan. Warm air is passed over this after applying the coating material to remove the coating solvent. It is extensively used in the preparation of controlled release products.

Solvent evaporation

Solvent evaporation – In this method, the coating material is dissolved in a volatile solvent, and the core material is dispersed in this. This mixture is agitated to produce a microcapsule. Heating is done to evaporate the solvent if needed. This technique has microcapsules of liquid and solid core materials of 5 to 5000 microns.

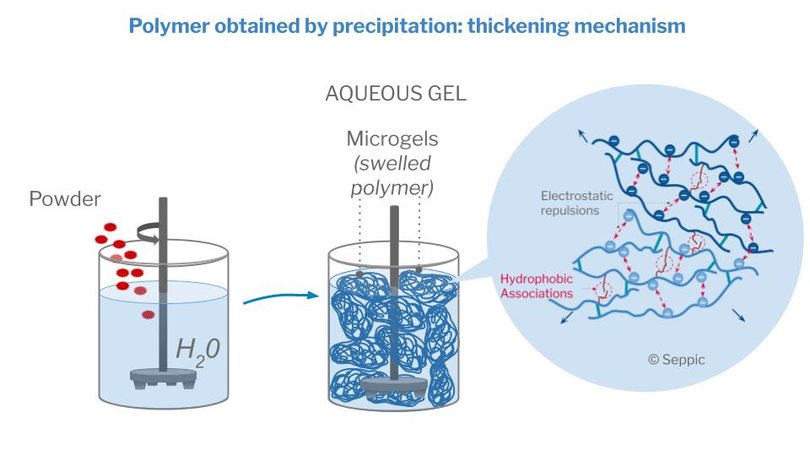

Polymerization

Polymerization – This technique involves polymerization techniques to form protective microcapsule coatings in situ. This happens due to the monomeric units’ reaction that is present at the interface existing between the core material and the coating material. The liquid or gaseous phase is used as the core material, and thus, the reaction occurs at the liquid-liquid, liquid–gas, solid-liquid, or solid-gas interface.

Read more:

- Microencapsulation involves the coating of particles ranging from several tenths of a micron to 5000 microns in size. Read Microencapsulation: Advantages and disadvantages

- Multiparticulate drug delivery systems consist of three common constituents: microparticles, microcapsules, and microspheres. Read Constituents of multiparticulate drug delivery system

- Microencapsulation is widely used to manufacture prolonged-release dosage forms, pulsatile release dosage forms, and targeted drug delivery systems. Read Applications of microencapsulation and challenges

- Article review

Pingback: Microencapsulation: Advantages and disadvantages > PharmaCampus

Pingback: Applications of microencapsulation and challenges > PharmaCampus

Pingback: Constituents of multiparticulate drug delivery system > PharmaCampus

Pingback: Is Big Data Analytics revamping the Pharmaceutical Industry? > PharmaCampus